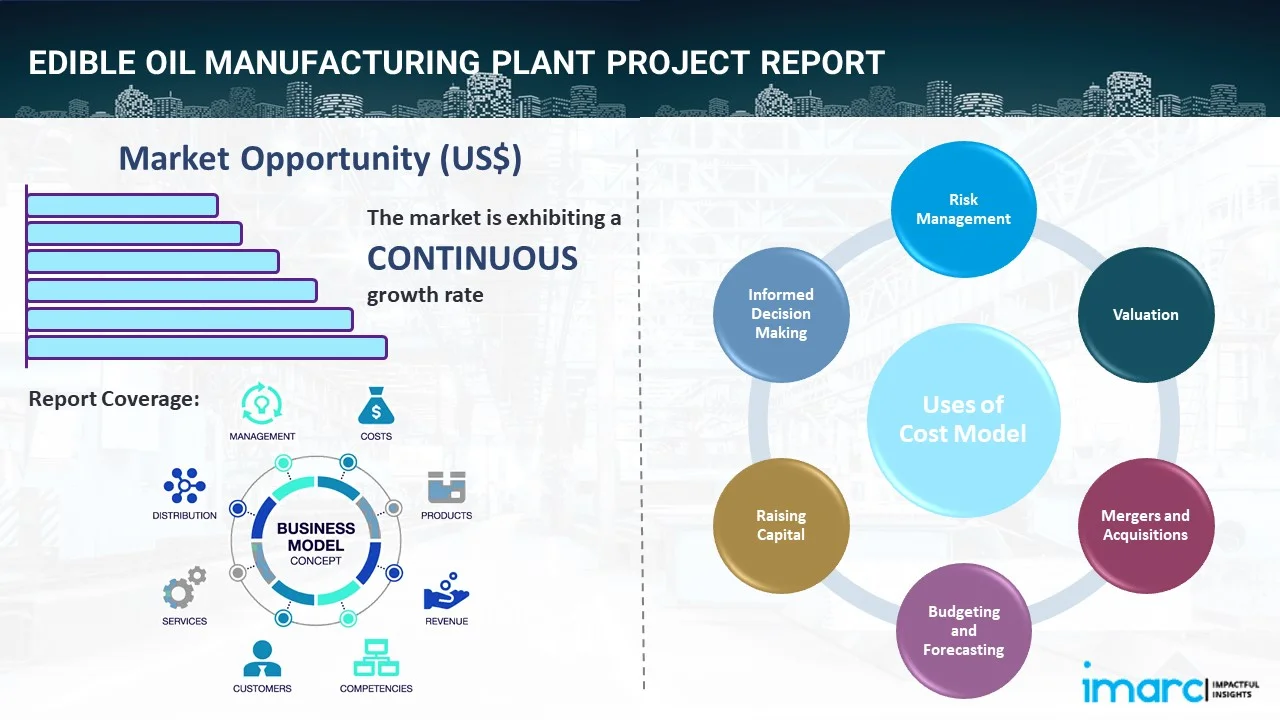

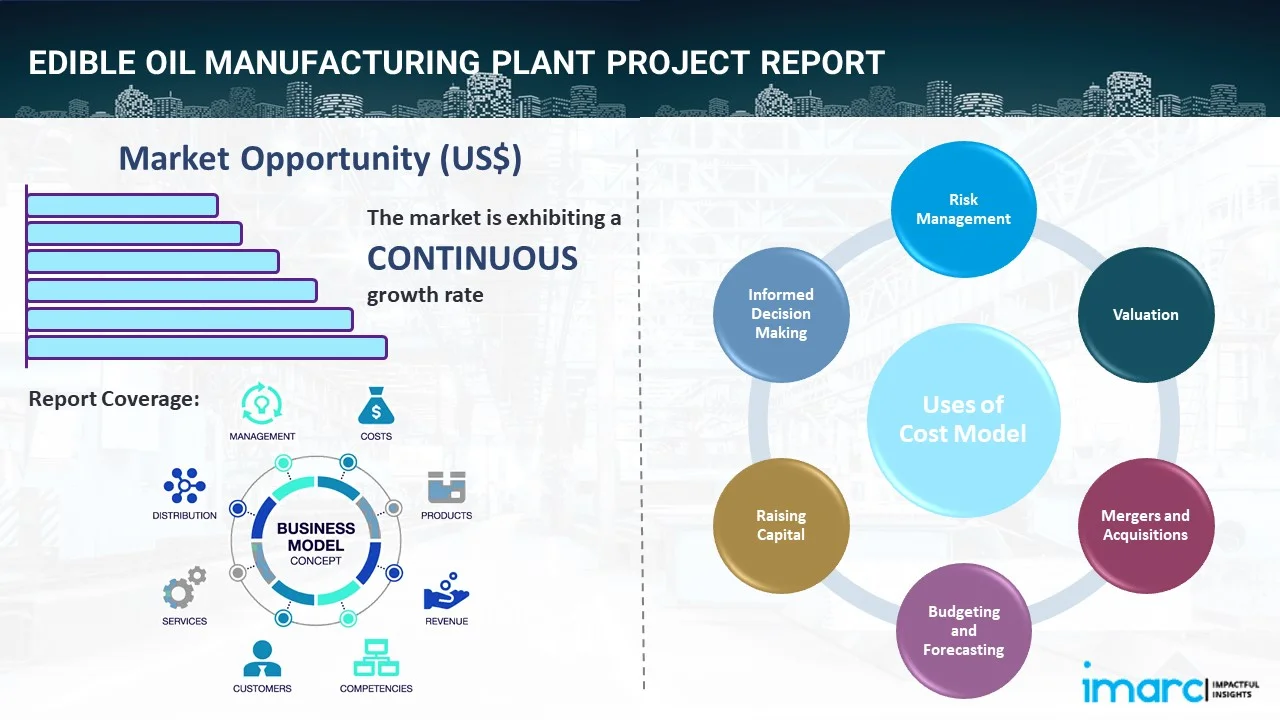

IMARC Group’s report, titled “Edible Oil Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up an edible oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report also provides detailed insights into project economics influencing the edible oil manufacturing plant cost, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Edible oil, a fundamental ingredient in culinary traditions worldwide, plays a pivotal role in cooking, flavoring, and nutrition. Derived from various plant and seed sources, such as olive, soybean, sunflower, and coconut, edible oils serve as cooking mediums, add richness to dishes, and provide essential fatty acids necessary for a balanced diet. Beyond its culinary significance, edible oil has a significant impact on global agriculture, trade, and health, as consumers increasingly seek healthier options and sustainable production methods. The versatile nature of edible oil makes it an indispensable component of daily cooking routines and a vital element in the food industry, reflecting its enduring relevance in modern kitchens and diets.

This ingredient offers a multitude of advantages and applications in culinary and industrial settings. Firstly, it serves as a versatile cooking medium, enabling frying, sautéing, and baking while enhancing the flavors of dishes. Edible oils also contain essential fatty acids that promote overall health, including heart health. They are a source of energy and aid in nutrient absorption. In addition to cooking, edible oils find applications in the food industry, serving as ingredients in salad dressings, sauces, and baked goods. Moreover, they are used in non-food sectors like cosmetics, pharmaceuticals, and biofuels. Their lubricating properties make them essential in machinery and industrial processes.

The edible oil market is shaped by a combination of market drivers and evolving trends that reflect changing consumer preferences, health consciousness, and global economic dynamics. The ever-increasing global population drives consistent demand for edible oils as they are a dietary staple in most cuisines. As urbanization rises, more people rely on convenient, pre-packaged foods and dine out frequently, leading to a higher demand for edible oils in the foodservice industry. Growing health awareness has led consumers to seek oils with healthier profiles, such as those low in saturated fats and high in unsaturated fats like olive and avocado oils. Economic development and rising incomes in emerging economies contribute to increased consumption of edible oils, as consumers have greater purchasing power. There is a growing trend towards healthier oil options, including cold-pressed, organic, and oil blends with health-promoting additives like omega-3 fatty acids. Consumers are increasingly interested in the transparency of the oil production process and product labeling, prompting companies to provide detailed information on sourcing and processing methods.

The following aspects have been covered in the edible oil manufacturing plant report:

The report provides insights into the landscape of the edible oil industry at the global level. The report also provides a segment-wise and region-wise breakup of the global edible oil industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of edible oil, along with the industry profit margins.

The report also provides detailed information related to the edible oil manufacturing process flow and various unit operations involved in a manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, expenditure, and other edible oil manufacturing plant setup. Additionally, the report provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

manufacturing-plant-raw-materials.webp)

The report also covers a detailed analysis of the project economics for setting up an edible oil manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the edible oil manufacturing plant report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up an edible oil manufacturing plant.

Profitability Analysis:

| Particulars | Unit | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 |

|---|---|---|---|---|---|---|

| Total Income | US$ | XX | XX | XX | XX | XX |

| Total Expenditure | US$ | XX | XX | XX | XX | XX |

| Gross Profit | US$ | XX | XX | XX | XX | XX |

| Gross Margin | % | XX | XX | XX | XX | XX |

| Net Profit | US$ | XX | XX | XX | XX | XX |

| Net Margin | % | XX | XX | XX | XX | XX |

| Report Features | Details |

|---|---|

| Product Name | Edible Oil |

| Report Coverage | Detailed Process Flow: Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements |

Land, Location and Site Development: Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs

Plant Layout: Importance and Essentials, Layout, Factors Influencing Layout

Plant Machinery: Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request)

Raw Materials: Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request)

Packaging: Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request)

Other Requirements and Costs: Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs

Project Economics: Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation

Financial Analysis: Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis

While we have aimed to create an all-encompassing edible oil plant project report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include: